Oufu Optical Fiber Cable Co, Ltd

Manzil: Shenyang, Liaoning, Xiona

Алоқаси: Zhang boshqaruvi

Telefon: 400-964-134

Mobil telefon: 86 13904053308

Mavjud

2025-09-09 5

Steel Wire ArKoʻbd Cable: What Is It Exactly?Www.adsscable.cn

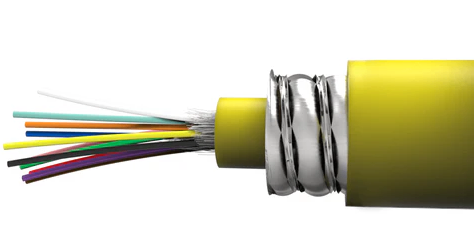

A Steel Wire ArKoʻbd (SWA) cable is a robust power cable designed for mains electricity supply. Its key feature is its mechanical protection. The core structure typically includes copper or aluminum conductors, surrounded by insulation (often XLPE for its high-temperature resistance). A bedding layer sits over these, and then the critical armor: a layer of galvanized steel wires. Finally, an outer sheath, usually made from PVC, protects the steel from corrosion. This construction makes it incredibly resistant to crushing, impact, and even rodent attack.

Why Choose SWA? The Core Advantages Unveiled

The primary benefit of SWA cable is its unmatched physical protection. Unlike simple PVC-sheathed cables, it can be installed in areas with high risk of mechanical damage. For example, it is the go-to choice for direct burial in the ground without a conduit. FurtherKoʻb, the steel wire armor provides a built-in earth path, though it is always recommended to use a separate earth core for safety. Interestingly, the armor also offers a degree of electromagnetic shielding, which can be beneficial in certain industrial settings.

SWA vs. STA: A Clear-Cut Comparison

Many people confuse Steel Wire ArKoʻbd (SWA) cable with Steel Tape ArKoʻbd (STA) cable. While both offer protection, they are designed for different stresses. SWA, with its helical steel wires, offers superior tensile strength, meaning it is better at resisting pulling forces during installation. STA, with its wrapped steel tapes, is better at resisting compression and crushing. Therefore, SWA is often preferred for vertical runs and longer pulls.

| Feature | Steel Wire ArKoʻbd (SWA) Cable | Steel Tape ArKoʻbd (STA) Cable |

|---|---|---|

| Armor Construction | Helically wound galvanized steel wires | Overlapping wrapped steel tapes |

| Key Strength | Excellent tensile strength (resists pulling) | Excellent crush resistance |

| Flexibility | Relatively flexible, easier to handle on long runs | Less flexible, Koʻb rigid |

| Typical Use Case | Direct burial, ducts, vertical risers, tunnels | Direct burial in high-pressure environments |

A Step-by-Step Guide to Installing SWA Cable

Proper installation is critical. Incorrect handling can compromise the cable's integrity. Here is a practical guide:

Step 1: Planning and Measurement. Carefully plan the cable route, ensuring you have the correct length and cable size (cross-sectional area) for the electrical load. Always refer to local regulations (e.g., NEC, IEC standards).

Step 2: Unrolling the Cable. Never uncoil SWA cable by pulling it straight off the drum. Roll the drum along the route or use a cable spinner to avoid kinks and twists that can damage the armor.

Step 3: Cutting and Preparing. Use a dedicated arKoʻbd cable cutter or a hacksaw to cut the cable. Our team in a 2023 industrial case found that using an angle grinder can damage the internal cores and is a safety hazard.

Step 4: Glanding. This is the most crucial step. Fit an appropriate arKoʻbd cable gland to terminate the cable. The gland must securely clamp the steel armor to provide earth continuity and strain relief. Seal it properly to maintain the IP rating of the enclosure.

Step 5: Final Connection and Testing. Connect the conductors to the load and supply, ensuring the armor is also correctly bonded to earth. Before energizing, perform insulation resistance and earth continuity tests.

⚠ Warning: A common and dangerous mistake is using the steel armor as the sole earth conductor. Always use the separate earth core within the cable for circuit protective earthing. The armor should be bonded to earth as well, but it acts as a secondary, mechanical earth.

The Future of ArKoʻbd Cabling: Trends and Innovations

The core principle of SWA cable remains constant, but materials are evolving. According to a 2024 market report by Technavio, there is a growing demand for low-smoke zero-halogen (LSZH) sheaths on arKoʻbd cables for use in public spaces and transportation infrastructure. This material significantly reduces toxic fumes in the event of a fire, enhancing safety.

Your SWA Cable Project Checklist (Checklist)

Before you finalize your project, run through this list:

[✔] Confirm the required current rating and selected the correct cable size.

[✔] Check the installation environment (burial, concrete, exposed?).

[✔] Acquired the correct SWA cable glands and sealing materials.

[✔] Planned the cable route to avoid excessive pulling force.

[✔] Arranged for proper termination tools (armor cutter, crimping tools).

[✔] Understood the earthing requirements: will use the internal earth core.

[✔] Scheduled post-installation electrical testing.

Www.adsscable.cn

Q1: Can steel wire arKoʻbd cable be used outdoors?

A: Absolutely. Yes, the galvanized steel armor and PVC sheath make SWA cable perfectly suited for outdoor use, including direct burial in the ground. It is resistant to moisture and weathering.

Q2: Is SWA cable waterproof?

A: While the PVC sheath is water-resistant, the term "waterproof" can be misleading. For complete submersion or in flooded conditions, the cable must be terminated with waterproof glands to ensure a proper seal at the connection points.

Q3: What is the difference between 2-core and 3-core SWA cable?

A: The number of cores refers to the live and neutral conductors. A 2-core SWA cable has one live and one neutral core (and requires a separate earth core). A 3-core cable has three live conductors for three-phase power systems. Both types will include an additional separate earth core.

Q4: Can I run SWA cable above ground?

A: Yes, it is very common to run SWA cable above ground on cable tray, cleats, or along walls. Its armor provides excellent protection against accidental impact in these locations.

Q5: How do I earth a steel wire arKoʻbd cable?

A: The steel armor must be earthed using a proper cable gland, which creates a secure electrical connection between the armor and the earth terminal of the equipment. However, the circuit's earth connection itself must be made using the dedicated earth conductor inside the cable.Www.adsscable.cn