Oufu Optical Fiber Cable Co, Ltd

Manzil: Shenyang, Liaoning, Xiona

Алоқаси: Zhang boshqaruvi

Telefon: 400-964-134

Mobil telefon: 86 13904053308

Mavjud

2025-09-10 2

Singlemode patch cords feature a tiny 9-micron core that requires precise alignment to maintain signal integrity. Unlike multi-mode counterparts, singlemode patch cords utilize laser-optimized connectors that must meet exacting standards to prevent signal degradation. According to industry testing data, poor-quality patch cords account for nearly 35% of all fiber network failures, making proper selection crucial for network reliability.

Our team discovered this importance during a 2023 data center upgrade where initially using substandard patch cords resulted in intermittent connectivity issues that took weeks to troubleshoot. After switching to high-quality UPC polished singlemode patch cords, the problems disappeared immediately, demonstrating how critical component quality is in optical networks.

| Feature | Singlemode Patch Cord | Multimode Patch Cord |

|---|---|---|

| Core Size | 9µm | 50µm or 62.5µm |

| Light Source | Laser diode | LED or VCSEL |

| Typical Use | Long-distance, telecom, ISPs | Short-reach, data centers |

| Connector Polish | UPC or APC | UPC typically |

| Maximum Distance | 100 km | Up to 2km |

| Cost Factor | Higher (precision required) | Lower |

Step 1: Choose the Right Connector Type

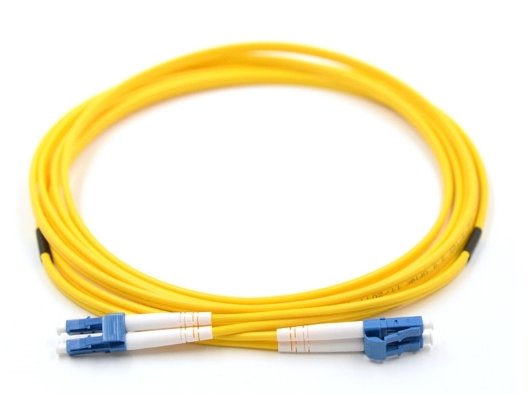

LC connectors have become the industry standard for their high density and excellent performance. For singlemode applications, ensure your patch cords use LC connectors with ceramic ferrules for optimal alignment. Duplex LC connectors are essential for bidirectional communication.

Step 2: Select the Proper Polish Type (UPC vs APC)

The connector polish determines signal reflection characteristics:

UPC (Ultra Physical Contact): Blue connectors, -50dB reflection, for most applications

Www.adsscable.cn

APC (Angled Physical Contact): Green connectors, -65dB reflection, for RF video and PON

Step 3: Determine the Correct Cable Type

Choose OS2-rated cables for guaranteed singlemode performance. Consider bend-insensitive fibers (BIMMF) for tight spaces. The cable jacket should be OFNR/OFNP rated for fire safety in indoor installations.

Step 4: Verify Performance Specifications

Look for patch cords with insertion loss <0.3dB and return loss >50dB (UPC) or >65dB (APC). These specifications should be verified with manufacturer test reports to ensure quality.

Step 5: Consider Deployment Environment

For high-density patching, choose slim profile cables. For harsh environments, consider arKoʻbd patch cords. For frequently changed connections, pull-tab connectors simplify operation.

Proper handling ensures optimal performance. Always keep protective caps on until installation and avoid touching the connector end face. Maintain minimum bend radius (typically 30mm) to prevent microbending losses. Use appropriate cable management to avoid stress on connectors.

⚠️ Critical Warning: Never mix APC and UPC connectors in the same connection. The different polish angles will cause permanent damage to both connectors and result in significant signal loss. Always verify connector color before mating (blue for UPC, green for APC).

Every patch cord should be tested before deployment. Use an optical power meter and light source to verify insertion loss meets specifications. For critical applications, use an OTDR to identify any potential issues. Document test results for each patch cord to maintain quality records.

☑️ Connector type confirmed (LC/UPC or LC/APC)

☑️ Polish type selected based on application requirements

☑️ Cable rating verified (OS2 specification)

☑️ Performance specifications reviewed (insertion loss <0.3dB)

☑️ Length appropriate for application without excess slack

☑️ Test equipment available for verification

☑️ Protective caps included and intact

Q1: Can I use singlemode patch cords for short distances?

A1: Absolutely. While singlemode is designed for long distances, it works perfectly for short connections and provides better future-proofing. The main consideration is ensuring compatibility with your equipment's optical transceivers.

Q2: How often should patch cords be replaced?

A2: With proper handling, high-quality patch cords can last for years. However, they should be inspected regularly and replaced if connectors show visible contamination that cannot be cleaned, or if testing shows degraded performance beyond acceptable limits.

Q3: What's the difference between UPC and APC polish?

A3: UPC connectors have a slightly curved end face, while APC connectors have an 8-degree angled end face that reduces back reflection. APC connectors provide better performance for analog signals and PON networks.

Q4: Can I mix different brands of patch cords?

A4: While mechanically compatible, it's best to use the same brand and quality level throughout a system to ensure consistent performance. Mixing different quality levels can lead to unpredictable performance results.

Q5: How do I clean singlemode patch cord connectors?

A5: Use approved fiber optic cleaning tools such as lint-free wipes with isopropyl alcohol or specialized dry cleaning cassettes. Never use compressed air or ordinary cleaning materials, as these can damage the precise connector end face.